📌 Pipe Selection by Project Type: A Guide from a Leading Pipe Supplier in the Middle East

- Pipekom

- Aug 9, 2025

- 2 min read

When it comes to large-scale infrastructure projects, selecting the right pipe material impacts performance, cost efficiency, and service life. As a trusted pipe supplier in the Middle East, Pipekom has worked with contractors across 17+ countries, delivering solutions for water, oil & gas, industrial, and municipal projects.

🌍 The Middle East pipeline market is valued at USD 10.2 billion in 2024 and projected to grow at 4%+ CAGR through 2030 — making the right material choice more important than ever.

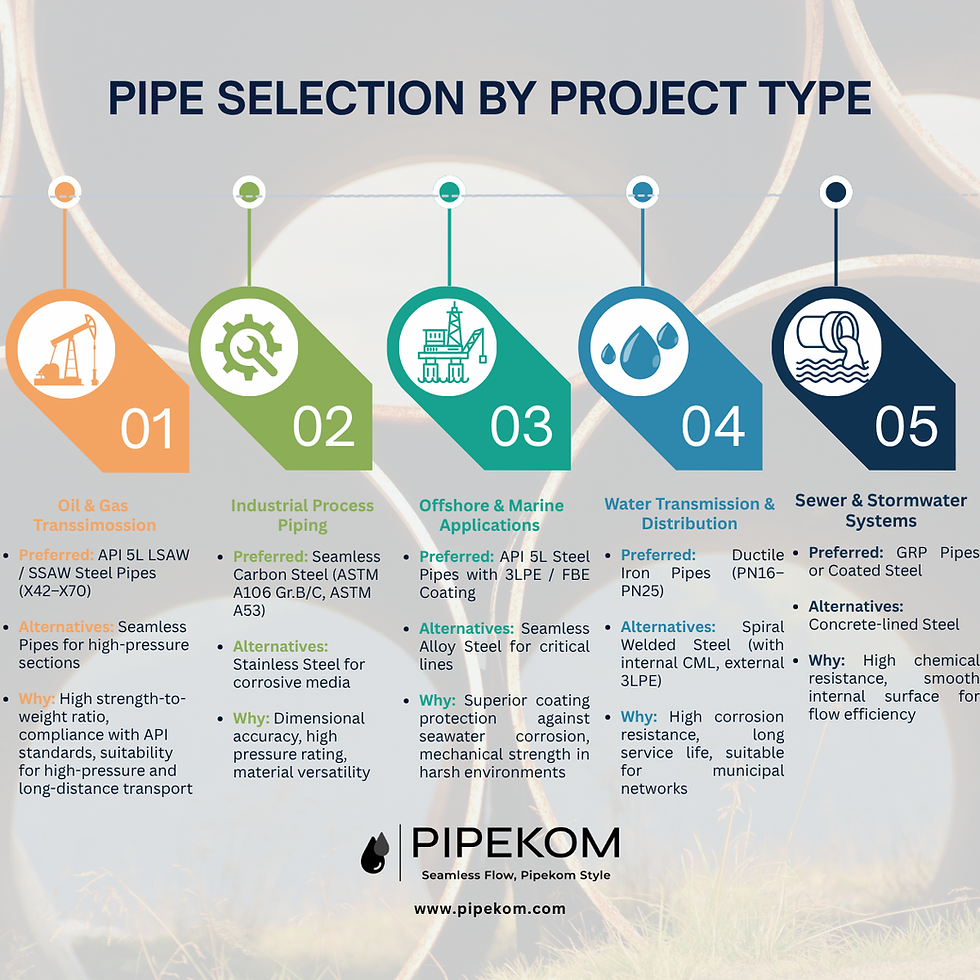

🛢 1️⃣ Oil & Gas Transmission

Preferred: API 5L LSAW / SSAW Steel Pipes (X42–X70)

Alternative: Seamless pipes for high-pressure zones

Why: Strength up to 550 MPa, designed for thousands of kilometers of safe transmission.

📊 Fact: The GCC invests USD 25B annually in oil & gas pipelines, with steel pipes dominating the market.

🏭 2️⃣ Industrial Process Piping

Preferred: Seamless Carbon Steel (ASTM A106 Gr.B/C)

Alternative: Stainless Steel for corrosive environments

Why: Precision dimensions, high pressure tolerance, and heat resistance up to 400°C.

⚓ 3️⃣Offshore & Marine Applications

Preferred: API 5L Steel with 3LPE / FBE

Alternative: Seamless Alloy Steel for critical use

Why: 3LPE extends service life 30+ years in seawater while maintaining structural integrity.

💧 4️⃣ Water Transmission & Distribution

Preferred: Ductile Iron Pipe (PN16–PN25)

Alternative: Spiral Welded Steel Pipe with Cement Mortar Lining (CML) + 3LPE coating

Why: DI pipes can last 100+ years, handle high pressures, and resist corrosion — ideal for municipal water networks in arid climates.

📊 Fact: Over 60% of Middle East municipal water projects in the last 5 years specified DI or coated steel pipes.

🌊 5️⃣ Sewer & Stormwater Systems

Preferred: GRP or Coated Steel Pipes

Alternative: Concrete-lined Steel

Why: High chemical resistance, smooth flow, and reduced maintenance.

Why Contractors Choose Pipekom

✅ Regional Presence: Delivery across the Middle East & Africa from hubs in Turkey, China, and Europe.

✅ Technical Expertise: Tailored solutions for each project type.

✅ Fast Delivery: Production, coating, testing, and shipping in 3–6 weeks.

📩 In a region with strict timelines and harsh environments, a proven pipe supplier in the Middle East is your best guarantee of success.